Goulds 45GS20412CL, 45GPM, 2HP, 230V, 3 Wire, 4" Stainless Steel Submersible Well Pump

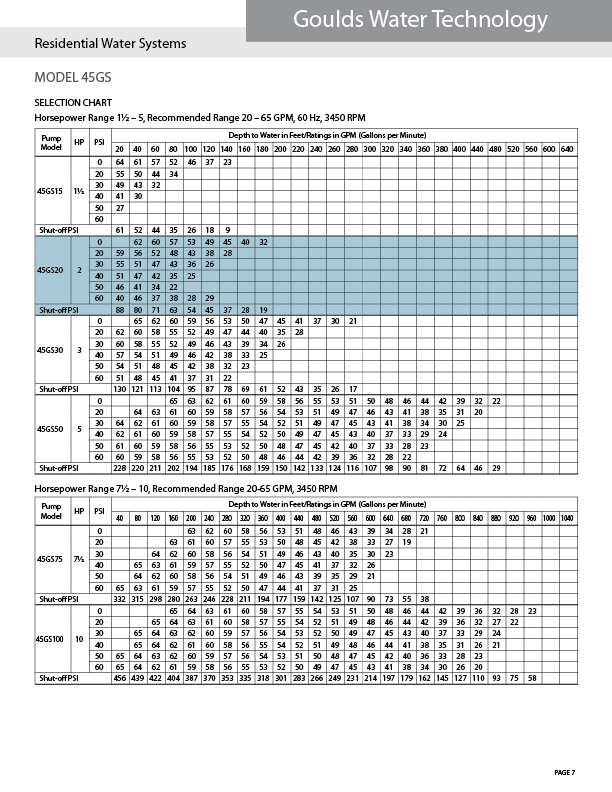

| Pump Model | HP | PSI | Depth to Water in Feet/Ratings in GPM (Gallons per Minute) | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 220 | 240 | 260 | 280 | 300 | 320 | 340 | 360 | 380 | 400 | 440 | 480 | 520 | 560 | 600 | 640 | |||

| 45GS15 | 1½ | 0 | 64 | 61 | 57 | 52 | 46 | 37 | 23 | |||||||||||||||||||

| 20 | 55 | 50 | 44 | 34 | ||||||||||||||||||||||||

| 30 | 49 | 43 | 32 | |||||||||||||||||||||||||

| 40 | 41 | 30 | ||||||||||||||||||||||||||

| 50 | 27 | |||||||||||||||||||||||||||

| 60 | ||||||||||||||||||||||||||||

| Shut-off PSI | 61 | 52 | 44 | 35 | 26 | 18 | 9 | |||||||||||||||||||||

| 45GS20 | 2 | 0 | 62 | 60 | 57 | 53 | 49 | 45 | 40 | 32 | ||||||||||||||||||

| 20 | 59 | 56 | 52 | 48 | 43 | 38 | 28 | |||||||||||||||||||||

| 30 | 55 | 51 | 47 | 43 | 36 | 26 | ||||||||||||||||||||||

| 40 | 51 | 47 | 42 | 35 | 25 | |||||||||||||||||||||||

| 50 | 46 | 41 | 34 | 22 | ||||||||||||||||||||||||

| 60 | 40 | 46 | 37 | 38 | 28 | 29 | ||||||||||||||||||||||

| Shut-off PSI | 88 | 80 | 71 | 63 | 54 | 45 | 37 | 28 | 19 | |||||||||||||||||||

| 45GS30 | 3 | 0 | 65 | 62 | 60 | 59 | 56 | 53 | 50 | 47 | 45 | 41 | 37 | 30 | 21 | |||||||||||||

| 20 | 62 | 60 | 58 | 55 | 52 | 49 | 47 | 44 | 40 | 35 | 28 | |||||||||||||||||

| 30 | 60 | 58 | 55 | 52 | 49 | 46 | 43 | 39 | 34 | 26 | ||||||||||||||||||

| 40 | 57 | 54 | 51 | 49 | 46 | 42 | 38 | 33 | 25 | |||||||||||||||||||

| 50 | 54 | 51 | 48 | 45 | 42 | 38 | 32 | 23 | ||||||||||||||||||||

| 60 | 51 | 48 | 45 | 41 | 37 | 31 | 22 | |||||||||||||||||||||

| Shut-off PSI | 130 | 121 | 113 | 104 | 95 | 87 | 78 | 69 | 61 | 52 | 43 | 35 | 26 | 17 | ||||||||||||||

| 45GS50 | 5 | 0 | 65 | 63 | 62 | 61 | 60 | 59 | 58 | 56 | 55 | 53 | 51 | 50 | 48 | 46 | 44 | 42 | 39 | 32 | 22 | |||||||

| 20 | 64 | 63 | 61 | 60 | 59 | 58 | 57 | 56 | 54 | 53 | 51 | 49 | 47 | 46 | 43 | 41 | 38 | 35 | 31 | 20 | ||||||||

| 30 | 64 | 62 | 61 | 60 | 59 | 58 | 57 | 55 | 54 | 52 | 51 | 49 | 47 | 45 | 43 | 41 | 38 | 34 | 30 | 25 | ||||||||

| 40 | 62 | 61 | 60 | 59 | 58 | 57 | 55 | 54 | 52 | 50 | 49 | 47 | 45 | 43 | 40 | 37 | 33 | 29 | 24 | |||||||||

| 50 | 61 | 60 | 59 | 58 | 56 | 55 | 53 | 52 | 50 | 48 | 47 | 45 | 42 | 40 | 37 | 33 | 28 | 23 | ||||||||||

| 60 | 60 | 59 | 58 | 56 | 55 | 53 | 52 | 50 | 48 | 46 | 44 | 42 | 39 | 36 | 32 | 28 | 22 | |||||||||||

| Shut-off PSI | 228 | 220 | 211 | 202 | 194 | 185 | 176 | 168 | 159 | 150 | 142 | 133 | 124 | 116 | 107 | 98 | 90 | 81 | 72 | 64 | 46 | 29 | ||||||

| Pump Model | HP | PSI | Depth to Water in Feet/Ratings in GPM (Gallons per Minute) | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 80 | 120 | 160 | 200 | 240 | 280 | 320 | 360 | 400 | 440 | 490 | 520 | 560 | 600 | 640 | 680 | 720 | 760 | 800 | 840 | 880 | 920 | 960 | 1000 | 1040 | |||

| 45GS75 | 7½ | 0 | 63 | 62 | 60 | 58 | 56 | 53 | 51 | 48 | 46 | 43 | 39 | 34 | 28 | 21 | ||||||||||||

| 20 | 63 | 61 | 60 | 57 | 55 | 53 | 50 | 48 | 45 | 42 | 38 | 33 | 27 | 19 | ||||||||||||||

| 30 | 64 | 62 | 60 | 58 | 56 | 54 | 51 | 49 | 46 | 43 | 40 | 35 | 30 | 23 | ||||||||||||||

| 40 | 65 | 63 | 61 | 59 | 57 | 55 | 52 | 50 | 47 | 45 | 41 | 37 | 32 | 26 | ||||||||||||||

| 50 | 64 | 62 | 60 | 58 | 56 | 54 | 51 | 49 | 46 | 43 | 39 | 35 | 29 | 21 | ||||||||||||||

| 65 | 63 | 61 | 59 | 57 | 55 | 52 | 50 | 47 | 44 | 41 | 37 | 31 | 25 | |||||||||||||||

| Shut-off PSI | 332 | 315 | 298 | 280 | 263 | 246 | 228 | 211 | 194 | 177 | 159 | 142 | 125 | 107 | 90 | 73 | 55 | 38 | ||||||||||

| 45GS100 | 10 | 0 | 65 | 64 | 63 | 61 | 60 | 58 | 57 | 55 | 54 | 53 | 51 | 50 | 48 | 46 | 44 | 42 | 39 | 36 | 32 | 28 | 23 | |||||

| 20 | 65 | 64 | 63 | 61 | 60 | 58 | 57 | 55 | 54 | 52 | 51 | 49 | 48 | 46 | 44 | 42 | 39 | 36 | 32 | 27 | 22 | |||||||

| 30 | 65 | 64 | 63 | 62 | 60 | 59 | 57 | 56 | 54 | 53 | 52 | 50 | 49 | 47 | 45 | 43 | 40 | 37 | 33 | 29 | 24 | |||||||

| 40 | 65 | 64 | 62 | 61 | 60 | 58 | 56 | 55 | 54 | 52 | 51 | 49 | 48 | 46 | 44 | 41 | 38 | 35 | 31 | 26 | 21 | |||||||

| 50 | 65 | 64 | 63 | 62 | 60 | 59 | 57 | 56 | 54 | 53 | 51 | 50 | 48 | 47 | 45 | 42 | 40 | 36 | 33 | 28 | 23 | |||||||

| 60 | 65 | 64 | 62 | 61 | 59 | 58 | 56 | 55 | 53 | 52 | 50 | 49 | 47 | 45 | 43 | 41 | 38 | 34 | 30 | 26 | 20 | |||||||

| Shut-off PSI | 456 | 439 | 422 | 404 | 387 | 370 | 353 | 335 | 318 | 301 | 283 | 266 | 249 | 231 | 214 | 197 | 179 | 162 | 145 | 127 | 110 | 93 | 75 | 58 | ||||

The Goulds 45GS20412CL is a high-performance submersible well pump designed for efficiency and durability. It offers a flow rate of 45 gallons per minute with a powerful 2 horsepower motor, making it ideal for various well applications.

Key Features

- Continuous Operation: Operates continuously without motor damage, adhering to motor manufacturer's limits.

- Field Serviceable: Designed with left-hand threads for easy maintenance using common tools.

- Sand Handling Design: Features a floating impeller stack for superior sand handling and durability.

- FDA Compliant Parts: Non-metallic parts made from corrosion-resistant, glass-filled composites.

- Stainless Steel Construction: Strong, corrosion-resistant polished stainless steel casing.

- Built-in Check Valve: Constructed from stainless steel and FDA compliant BUNA rubber for quiet operation.

- Hex Shaft Design: Ensures positive impeller drive with its six-sided shafts.

- Engineered Polymer Bearings: Abrasion-resistant bearings made from proprietary polymer material.

Specifications

- Manufacturer: Goulds

- Model Number: 45GS20412CL

- Power: 2 HP

- Voltage: 230V

- Phase: 1

- Amperage: 9.9 Amps

- Wire Count: 3 Wire

- Diameter: 4 inches

- Shipping Weight: 57 lbs

- UPC: 69766679460

Installation Note

Ensure proper operation by using a "Dole" flow restriction valve to prevent upthrust damage. Maintain flow within the pump's recommended range.

Electrical Wire Gauge Chart

| Copper Wire Size | 12 Gauge | 10 Gauge | 8 Gauge | 6 Gauge | 4 Gauge | 2 Gauge |

|---|---|---|---|---|---|---|

| Distance from service entrance to motor | 286 ft. | 456 ft. | 722 ft. | 1123 ft. | 1790 ft. | 2843 ft. |

Free Shipping

This product qualifies for free shipping, making it a convenient and cost-effective choice for your well pump needs.

•Powered by CentriPro Motors The motors feature built-in lightning/surge protection. All have a 700# thrust bearing as compared to our major competitor's 300# and 650# ratings. The 1/2 - 3 HP, 3-wire and all 2-wire models have on- winding thermal overloads.

•Powered for Continuous Operation: All ratings are within the working limits of the motor as recommended by the motor manufacturer. The pump can be operated continuously without damage to the motor.

•Field Serviceable: Units have left hand threads and are field serviceable with common tools and readily available repair parts.

•Sand Handling Design: Our face clearance, floating impeller stack has proven itself for over 40 years as a superior sand handling, durable pump design.

•FDA Compliant Non-Metallic Parts: Impellers, diffusers, and bearing spiders are constructed of glass-filled engineered composites. They are corrosion resistant and non-toxic.

•Discharge Head/Check Valve: Cast 303 stainless steel for strength and durability. Two cast-in safety line loops for installer convenience. The built-in check valve is constructed of stainless steel and FDA compliant BUNA rubber for abrasion resistance and quiet operation.

•Motor Adapter: Cast 303 stainless steel for rigid, accurate alignment of pump and motor. Easy access to motor mounting nuts using standard open end wrench.

•Stainless Steel Casing:Polished stainless steel is strong and corrosion resistant.

•Hex Shaft Design: Six sided shafts for positive impeller drive.

•Engineered Polymer Bearings:The proprietary, engineered polymer bearing material is strong and resistant to abrasion and wear. The enclosed upper bearing is mounted in a durable Noryl® bearing spider for excellent abrasion resistance.

| Phase | 1 |

|---|---|

| Voltage | 230v |

| Wire Count | 3 Wire |

| Motor Horsepower | 2 |

| Flow Rate | 45 |

| Material | Stainless Steel |

| Diameter | 4 inch Diameter |

| Source | https://www.xylem.com/ |

| Model # | 45GS20412CL |

| Manufacturer | Goulds |

| Performance Chart | Goulds Performance Chart 45GS |

| Shipping Weight | 57 |

Electrical Wire Gauge Required for a 2 HP, 3 Wire, 230V, 1 Phase Motor

| Copper Wire Size | 12 Guage | 10 Gauge | 8 Gauge | 6 Gauge | 4 Gauge | 2 Gauge |

| Distance from service entrance to motor | 286 ft. | 456 ft. | 722 ft. | 1123 ft. | 1790 ft. | 2843 ft. |

Goulds Pumps Inc. began in the mid-19th century as the world’s first manufacturer of iron pumps and has grown to become the world’s largest manufacturer of industrial, agricultural, and consumer pumps. The company is organized into two main groups: Water Technologies, which serves municipal water systems, the agricultural market, and the residential market; and Industrial Products, which serves several markets, including the chemical industry, the petroleum industry, and the pulp-and-paper industry. Like other companies in the fluid technology business, Goulds Pumps’ sales and earnings are dependent on overall economic conditions. A downturn in the economy or in one of Goulds’ markets can result in reduced orders and flat earnings. After a period of ups and downs in the 1980s and 1990s, Goulds Pumps was acquired in 1997 by ITT Industries, Inc., a global diversified manufacturing company based in White Plains, New York. Goulds Pumps continues to operate as a wholly owned subsidiary of ITT Industries as part of its fluid technology segment.

Early History

Although Goulds Pumps dates its corporate anniversary from 1848, the company’s roots began in 1840, when Abel Downs began manufacturing wooden pumps in a former cotton factory in Seneca Falls, New York. Downs teamed with John Wheeler, and the two were joined in 1846 by Edward Mynderse, who owned a large amount of property in the area, to form a company that became Downs, Mynderse and Co. in 1848, the official founding of Goulds Pumps.

Seabury S. Gould was also working on pumps in his shop in Seneca Falls, and in the mid-1840s oversaw the casting and assembling of the world’s first all-metal pump. Gould served as president of Downs, Mynderse and Co. from 1848 to 1872. He bought out Mynderse and H. C. Silsby, another co-owner, in 1851, and the company’s name was changed to Downs and Company. Downs and Company constructed a new plant in 1853, and in 1864 the company was incorporated in the state of New York. In 1869, the name Goulds Manufacturing Company was adopted.

Seabury Gould probably could not envision all the uses to which his all-metal pumps would be put. At that time they solved a problem associated with trains and their need for water. They were served by windmill-driven pumps, which often caused trains to be delayed for up to a day. Eventually, the problem was solved by steam-powered pumps that were developed in Gould’s shops.

Seabury Gould was succeeded by his son, James H. Gould, who served as president from 1872 to 1896. With the nation rapidly expanding westward, it was a period of great activity in the pump business. Proliferating agriculture, ranching, lumbering, mining, and manufacturing were growing markets for a wide range of pumps. Suction pumps, lift pumps, and power, steam, and piston pumps were introduced to meet their needs.

In 1900 a second plant was constructed in Seneca Falls to produce Goulds’ “Triplex” pumps, under the presidency of Seabury S. Gould II (1896-1908), He was followed by Norman Judd Gould, who served as president from 1908 to 1964. The company’s present name, Goulds Pumps Inc., was adopted in March 1926.

In 1944 Goulds Pumps received the Army-Navy “E” Award for outstanding production of war material. Sales in that year reached $10 million. In 1945 Goulds Pumps produced its largest pump to date. To be used on a petroleum pipeline, the horizontal pump had a 36-inch stroke and required three railroad flat cars to ship. After World War II, Goulds Pumps developed new pump lines for water systems and general industry. The company expanded by making acquisitions and opening branch offices in the United States. It gradually expanded operations throughout the world.

With the death of Norman Judd Gould in 1964, control of the company passed from the Gould family. Most of the company’s stock was now owned by the general public and by employees of the company. The company grew from sales of $15.9 million in 1960 to $45 million in 1969. It acquired U.S. Pumps, Inc., with plants in Los Angeles and Lubbock, Texas; Goyne Pump Co. of Ashland, Pennsylvania; and Morris Pump Co. of Baldwinsville, New York. It also entered into a joint venture with Oil Dynamics, Inc., to manufacture submersible pump units for oil wells.

Recent History

Although the 1970s began with an economic recession, pump sales reached record levels during the decade and continued at record levels in the early 1980s. Goulds sales rose from $48.8 million in 1970 to $239 million in 1980. Expectations in the fluid technology industry were unreasonably high. Pump companies could not keep up with the demand, as major projects were being built in the Middle East, oil shortages were projected, and a lot of money was being spent on new projects. Eventually the bubble burst, and pump manufacturers were caught with excess capacity and had to fight for survival. As a result, Goulds and other pump companies had to reduce their workforces to remain competitive.

In 1981, Goulds’ sales were $308.7 million and falling. In late 1981 Goulds suffered through a bitter labor strike that was marked by vandalism and harassment of non-striking workers. Two years later sales stood at $275.3 million.

Stephen Ardia Became CEO, 1985

By 1985 the company needed to be revitalized after its poor financial performance and labor troubles. Stephen Ardia was named CEO of Goulds Pumps. He introduced a commitment to quality and participatory management. He was able to focus the company’s culture on “looking for opportunities to improve how we’re doing and what we’re doing; much greater involvement of our people; and a greater openness to ideas and ways that other people do things,” he told the Rochester Business Journal.

Ardia had risen through the ranks at Goulds, starting at the company in 1965 as an applications engineer. The two areas he focused on were participatory management and total quality. Under his leadership, CATS (Competitive Advantage Through

Simplification) was introduced to update and cut through the company’s 140-year accumulation of procedures. CATS was designed to reduce the costs of entering, handling, and billing orders. Other systems were revamped and updated under the CATS program, with savings estimated at $7.5 million over four years.

However, the company’s future was still uncertain. Declining oil prices had slowed exploration and production, and the pump market was dependent on a growing petroleum business. However, Goulds had already begun negotiating its entry into the Chinese market. By early 1988, the company had completed talks to establish a joint venture with the Nanjing Deep Well Company of China. The venture was expected to produce some 600 pump units for four petrochemical plants in China. Production on units for two of the four plants had already begun in March 1987 at Goulds’ Seneca Falls facility.

Goulds began building its export business around 1980. By 1988 it had offices in Singapore, South Korea, Hong Kong, and Jakarta, and a representative in Beijing. Goulds’ Industrial Products group already had an established presence in China, where it manufactured industrial pumps for sale in the United States. According to Juergen Schulz, Goulds’ director of international sales, it was the company’s presence in China that initially “allowed us the opportunity to make inroads to sell products made here in the United States.” Goulds was also acquiring companies in other countries. In 1985 it acquired a company in Lowara, Italy, for $19.8 million, which grew from about $30 million in sales to more than $100 million by 1991.

Ardia Achieved Record Sales After Five Years in 1990

By 1990 Goulds Pumps had more than 1,900 employees in New York and more than 3,000 in North America. Sales rose to $554.7 million, a nine percent increase over the 1989 figure. Net income from continuing operations increased six percent to $30.6 million. Goulds Pumps continued to grow globally. It marketed its products in more than 90 countries and was expanding its production facilities into other countries. International sales of $192 million accounted for 35 percent of the company’s total revenues. Overall, the Industrial Products group represented 62 percent of sales, with the remaining 38 percent coming from Water Technologies.

The next year net sales reached $566.6 million, and earnings inched up to $30.7 million in a year of economic recession. The company was named to the Covenant 200, an honor roll of the most responsible big corporations in the United States. “Our diversification comes through the many markets we serve,” Ardia told the Rochester Business Journal. “We’re not dependent upon any single industry. We serve the water systems market, the chemical industry, the petroleum industry, the pulp-and-paper industry, and we serve markets outside the United States.” Other factors contributing to Goulds’ rebound from its 1980s slump included improving service to its customers, increasing market share, introducing new products, and enhancing productivity.

Company Perspectives

We will focus on continuing to improve operations and serving customers better and more efficiently through our global distribution networks. The fluid businesses of ITT Industries and Goulds will accelerate their progress in complementary business services.

The company was organized into two main groups, Water Technologies and Industrial Products. Water Technologies over the past ten years had increased its market share from 15 percent to 25 percent. About half of its business was produced in the United States and half outside the U.S. Industrial Products held about 20 percent of the industrial market share in the United States, up from about 15 percent in 1986. Of $350 million in industrial business, $95 million came from export sales. The company did not have a large manufacturing facility overseas. Global market share for industrial products was estimated at eight to 10 percent.

Globalization was perceived as an opportunity for growth. International sales accounted for about 40 percent of Goulds Pumps’ business in the early 1990s. Key areas for growth were the Asia-Pacific area and Latin America. International expansion occurred in Venezuela, where the company acquired the remaining 80 percent of its investment in 1991 to become the largest pump company in that country. Another company in Mexico was wholly owned. In 1992 the company opened a manufacturing facility in Korea.

Period of Flat Sales in Difficult Economic Times, Early 1990s

Sales were flat from 1990 to 1993, hovering around $555 million. The period 1992-93 was seen as a cyclical low point. There was a recession, and the whole process industry was down. Goulds reduced its U.S. workforce from 3,100 to 2,746 in January 1992, mostly through early retirement incentives and attrition.

In October 1993 Goulds acquired Environamics, Inc., a privately owned company in New Hampshire. A start-up company, Environamics had developed and patented hermetically sealed pump technology that Goulds could use in its pumps for the chemical processing industry. After recording pre-tax losses of approximately $3 million in 1994 and 1995, ownership of Environamics was transferred back to two senior managers at Environamics.

New President and CEO in 1994

Thomas McDermott, a former president and chief operating officer of Bausch & Lomb Inc., replaced Stephen Ardia as president and CEO in July 1994. He had been a member of Goulds’ board of directors since 1988. In May 1995 he was also named chairman of the board.

Under Ardia, Goulds had been beset by lackluster performance in the 1990s. Sales hovered around $555 million, but net earnings from continuing operations (before extraordinary charges and cumulative effects of accounting changes) fell from $31.3 million in 1991 to $21.8 million in 1992, then recovered in 1993 to $23.5 million. In 1994 the company reported net sales of $585.5 million and net earnings of $18.2 million.

Ardia was credited with solving Goulds’ labor problems by instituting participatory management and total quality management programs, and he brought sagging sales and earnings up to respectable levels. However, as earnings drifted lower, the company began to experience other problems. It had environmental problems with a consumer pump in California. A lawsuit over alleged health risks from the pump caused the company’s stock price to dip by 20 percent. Then it was hit with a shareholder suit that claimed Ardia hid the problem to prevent Goulds’ stock price from falling. In mid-1995 Goulds agreed to a $300,000 out-of-court settlement.

McDermott kept Goulds’ management team in place as he introduced a sweeping five-point plan that closely followed Ardia’s agenda: cut costs; increase inventory turnover; expand global business; grow through acquiring related businesses and expanding market share; and change the corporate culture. He eventually created a new top management team, hiring or promoting 15 executives to upper-level posts.

In the first several months of McDermott’s tenure, the company acquired an Austrian pump company and sold its 50 percent interest in Oil Dynamics Inc., a Tulsa, Oklahoma-based pump manufacturer for oil rigs. These moves were indicative of McDermott’s desire to build global market share and refocus the company’s domestic business. Pumpenfabrik Ernest Vogel AG was the leading pump manufacturer in Austria with 1993 sales of $60 million. The acquisition was valued at approximately $51 million, including the assumption of some $34 million in debt.

Corporate Headquarters Moved in 1995

In 1995 McDermott separated the company’s corporate offices from its manufacturing operations and moved the company’s headquarters from Seneca Falls to Fairport, near Rochester. He believed managers were too close to the company’s operations; with added distance, he thought they would be able to better focus on strategic rather than operational issues. It was a move to spur change in the company’s corporate culture.

Sales jumped in 1995 to $718.8 million, but earnings were flat at $18.1 million. However, the company was performing well under McDermott. Before restructuring charges, earnings per share were up 41 percent over 1994 and operating earnings rose more than 26 percent. The company took a pre-tax restructuring charge of $18.5 million in connection with its divestiture of Environamics and the closing of its manufacturing facilities in Venezuela. The operation in Venezuela had resulted in losses in almost every year since Goulds assumed ownership in 1990. Goulds would continue to maintain sales offices in Venezuela and make shipments there from its manufacturing facilities in the United States.

In 1996 Goulds reported revenues of $774 million and had more than 5,200 employees throughout the world. It was a major supplier to engineering contractors around the world. It was also the world’s leading manufacturer of residential well-water pump systems.

Goulds Acquired in 1997

In April 1997 ITT Industries, Inc., a global diversified manufacturing company based in White Plains, New York, announced it had reached an agreement with Goulds Pumps to acquire the company for approximately $815 million in cash plus the assumption of $119 million of Goulds’ debt. The acquisition would be accomplished through a tender offer to Goulds’ shareholders at $37 a share, which was completed in May.

According to Travis Engen, chairman, president, and CEO of ITT Industries, “This combination will create the world’s largest pump producer and contribute significant efficiencies for both growth and cost improvement.” With the addition of Goulds Pumps, ITT Industries’ fluid technology business would represent more than 20 percent of the company’s sales and contribute more than 25 percent of its operating income. Fluid technology was one of ITT Industries’ “most profitable and fastest-growing business segments,” said Engen.

The fit between Goulds and ITT Industries was expected to be a good one. On the one hand, Goulds was a leading producer of pumps for the industrial sector, while ITT Industries was a world leader in submersible pumps for municipal water treatment systems. In addition to cost efficiencies, ITT Industries noted there were important geographic efficiencies in the combination. Taking the Pacific Rim as an example, ITT Industries had distribution points in Australia, New Zealand, Vietnam, and several Central Asian republics, while Goulds had distribution facilities in The Philippines, Korea, and Thailand. Both companies had operations in China, Taiwan, Singapore, Malaysia, and Indonesia. In Latin America, Goulds’ presence in Venezuela and Mexico complemented ITT Industries’ operations in Chile, Argentina, and Brazil.

The two companies together would serve more than 130 nations. Engen noted, “The industry’s growth and profit potential is most promising in the developing world, where the combined company will have access to the full range of infrastructure-related and industrial markets.”

ITT Industries’ fluid technology business specialized in the manufacture of pumps, valves, heat exchangers, and related equipment used to move, measure, and control fluids. The company’s fluid technology segment had 1996 sales of $1.3 billion. Its markets included wastewater treatment, chemical processing, construction, bio-pharmaceutical, aerospace, and general industry.

With the acquisition of Goulds, ITT Industries’ fluid technology business increased 34.9 percent in 1997 to $1.8 billion. Operating income, excluding special charges, was $156.7 million, a 38.4 percent increase over 1996. Overall, ITT Industries had 1996 sales of $8.72 billion and was active in three primary business segments: fluid technology, automotive, and defense and electronics. In 1997 ITT Industries’ sales increased $59 million to $8.78 billion.

The takeover was a friendly one, with ITT Industries’ offer of $37 a share giving Goulds shareholders more value. The company’s stock was underperforming in spite of 20 percent increases in net earnings for the past two years. As part of ITT Industries, Goulds would keep its own name and operate as a wholly owned subsidiary. At first McDermott was undecided if he would stay on as head of Goulds, even though ITT Industries wanted him to. Then, in May 1997, the Rochester Business Journal reported that McDermott would leave Goulds once the buyout was completed.

Goulds Pumps Returned to Seneca Falls in 1998

It was announced that Goulds would move its corporate headquarters back to Seneca Falls by January 1, 1998. ITT Industries wanted to reintegrate Goulds’ corporate managers with the company’s production operations in Seneca Falls. McDermott and much of the top management team he had assembled had left Goulds. It was originally McDermott’s idea to separate top management from operations as a way to improve efficiency. Under McDermott’s leadership, Goulds’ bottom line and prospects improved significantly. Although ITT Industries tried to convince McDermott to stay on, he told the Rochester Business Journal, “I’m at a point where I don’t think I could work for somebody else.” Approximately half of McDermott’s management team left when he did.

Goulds 45GS20412CL, 45GPM, 2HP, 230V, 3 Wire, 4" Stainless Steel Submersible Well Pump

Goulds 45GS20412CL, 45GPM, 2HP, 230V, 3 Wire, 4" Stainless Steel Submersible Well Pump

Validate your login