- Welcome to Aqua Science

- Compare ()

- Water Wisdom

- Sign In

- Contact Us

- Create an Account

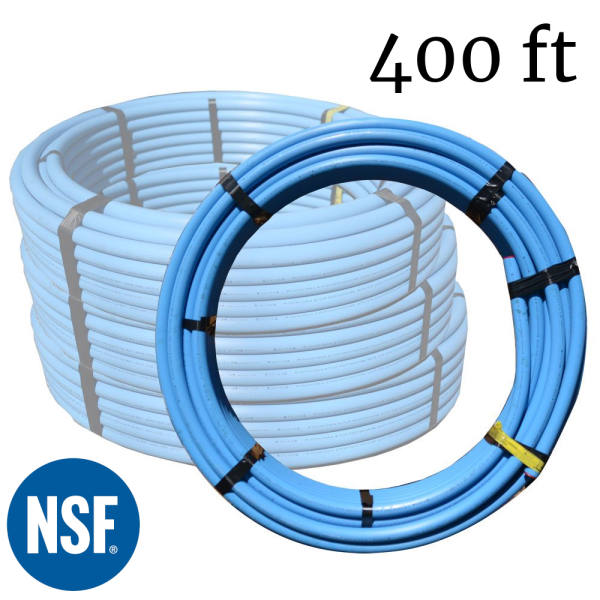

Endot Industries Submersible IPS Poly Pipe - 200PSI, 1" Diameter, 400ft.

SKU#

poly200psi-1inch-400ft

In stock

- Blue Color Coding: Easily identifiable as water pipe, meeting international standards.

- Clear Core: Made from virgin HDPE, ensuring no recycled materials are used—proof of quality.

- High Performance Resin: Built with PE 4710 resin, offering 25% higher pressure rating than standard PE 3608 pipes.

- Damage Visibility: Clear core reveals significant damage like cuts or gouges, unlike solid-colored pipes.

- Compatibility: Works seamlessly with all HDPE fittings and connectors.

- Installation Convenience: Features footage marks every two feet for easier setup.

- UV Stabilized: Protected against sunlight deterioration; underground installations can last up to 100 years.

- Permanent Markings: Embossed printing ensures durability over time.

- Certified Standards: Meets NSF-14, NSF-61, and AWWA C901-08 certifications for safety and reliability.

- Industry-Leading Warranty: Backed by a warranty with no time limit and unmatched labor reimbursement.

EndoPure is produced from PE 4710 resin providing the strongest, most durable pipe available. Product made with PE 4710 resin has a 25% higher pressure rating than PE 3408 pipe. EndoPure has a clear core of HDPE providing visible proof of quality and the assurance that no regrind materials have been used to produce EndoPure. EndoPure is produced from HDPE resin with a 50 year track record of quality and performance. This is the same resin used for much of the gas pipe installed in the USA. EndoPure is entirely compatible with all fittings and connectors made for HDPE water pipe and tubing. EndoPure has continuous consecutive footage marks every two feet to assist in installation. EndoPure is UV stabilized for protection from sunlight deterioration. EndoPure printing is permanently embossed. EndoPure is NSF Certified and meets AWWA C901 standards.

Company History

Endot Industries, Inc. was founded in 1972 with a mission - To provide our customers with the highest quality plastic pipe and conduit on a timely basis and at competitive prices. Production began in 1973 with one extruder making gas pipe from PE 3406 Ultra High Molecular Weight Polyethylene. Endot continues to make yellow gas pipe and tubing today. Over the next several years Endot grew and expanded it’s marketing efforts into the water pipe market. With the advent of PE3408 resins Endot began to focus primarily on water pipe products.

In 2001 Endot began producing all of our water pipe and tubing products using the high performance polyethylene resin known in Europe as PE-100 and now called PE 4710 in the United States. PE 4710 is a bi-modal resin with a 25% higher pressure capacity than PE 3408 and exceptional resistance to stress cracking and almost double the service life of PE 3408.

Endot has long been a leader in the small diameter polyethylene water pipe market.

With the acquisition of a polyethylene pipe competitor in 1990 and the 1998 acquisition of the assets of Orangeburg Industries, Endot significantly increased our market share in the water pipe market and added production facilities in Ohio and Tennessee. In April of 2003 Endot opened a production facility in Pryor Creek, OK (just East of Tulsa) with the capacity to produce Water Pipe, Gas Pipe and Conduit products. Endot's Oklahoma facility expanded our reach into the Western markets and increased our service levels in the Southwest.

Endot has become a nationwide producer of polyethylene water pipe for the water well, lawn irrigation and municipal water works markets and one of the largest small diameter HDPE water pipe producers in the USA. Endot’s newest product, EndoPure, was introduced in 1994. EndoPure is the first blue polyethylene water pipe designed to meet the color code standards of today’s utility markets. The clear core of EndoPure provides visual assurance of purity and that no contaminants will be transferred from the pipe to the water in it.

Endot innovation has resulted in EndoTrace, an HDPE water pipe or tube with a tracer wire attached to the pipe that facilitates locating the product in the underground. EndoTrace makes it possible to install a water service line and a tracer wire in one step saving on installation costs and assuring the pipe can be located if needed in the future. EndoTrace can be directionally bored into place.

When the first fiber optic cables were being installed in 1978, Endot began production of light guide innerducts. Innerduct is a small diameter tube used to subdivide larger 3.5” and 4” conduits designed for large diameter copper cables into 3 or 4 smaller channels more suited to small diameter fiber optic cables. Innerduct allows better utilization of the existing underground conduit systems, especially in major metropolitan area.

Endot was also one of the first companies to produce corrugated innerduct, a lighter weight innerduct that provides a significant reduction in friction when installing cables. Endocor Corrugated innerduct has lower friction than smoothwall innerduct and allows longer, unassisted, pulls of fiber optic cable.

Endot was the first company to produce a UL Listed Plenum Raceway to facilitate the installation fiber optic cable in office and factory buildings. Today Endot produces UL Listed Plenum and Riser innerduct in sizes from ½” through 2” thereby meeting the needs of the premise wiring market with the widest range of products available. Plenum Raceway is available in the colors White and Orange. Other colors are available on special order.

Today Endot has three production facilities and numerous distributors throughout the United States and Canada. With 25 extruders in three plants Endot can provide our distributor customers with a wide range of the highest quality products without delay. Endot corrugated innerduct products range in size from 1/4” through 2” and our pipe, tubing and smoothwall innerduct is produced from 1/2” through 8” sizes.

| Manufacturer | Endot Industries |

|---|---|

| Model # | poly200psi-1inch-400ft |

| Source | https://endot.com |

| Performance Chart | None |

| Gauge | 12 |

| Length | 400 ft. |

| Shipping Weight | 72 |

Endot Industries Submersible IPS Poly Pipe - 200PSI, 1" Diameter, 400ft.

Endot Industries Submersible IPS Poly Pipe - 200PSI, 1" Diameter, 400ft. $424.00

Validate your login